RC Components Motorcycle Wheels Buyers Guide

by Alex M • December 22, 2020

The pursuit of the perfect custom motorcycle begins with finding the right components which fill three vital elements: exceptional style, high quality, and reliability. While flashy aftermarket products are available for a wide array of motorcycles, one of the most eye catching and performance enhancing customizable components of a motorcycle still remains as the motorcycle wheels.

Motorcycle wheels not only serve as a customizable cosmetic component of a motorcycle, but also play a vital role in a motorcycle's performance, and a rider's safety. This requires the wheel not only to have an attractive design, but also to meet a demanding range of safety requirements and quality control.

In this day and age, many manufacturers have turned to outsourcing for certain stages of the manufacturing process of a product. Whether it be for CNC machining, polishing, chroming, or engineering; one thing is for certain, quality suffers when production is not completely controlled directly by the manufacturer.

In 1989, RC Components recognized the growing need for quality after-market motorcycle wheels which would truly meet the standards for innovative wheel designs, quality construction, and reliability. Since then, RC component wheels have been designed, engineered, and manufactured in Bowling Green, KY, all under the same roof. With over 30 years of refining the wheel manufacturing process, RC Components has become the industry pioneer of motorcycle wheels with dozens of available styles for Harley and metric cruiser motorcycles alike. Quality starts on the inside, and because the process is controlled internally, so is the ability to ensure quality wheels for each and every customer.

Choosing the Right Wheel Design

Choosing the right wheel design for your ride begins with understanding the sizing and fitment of your motorcycle wheel. RC Component wheels are designed as a direct bolt on installation including the bike specific hub, bearings, and all necessary hardware; however, certain applications may require additional components for proper installation. If choosing an oversized wheel size, additional modifications such as fender substitutes, triple tree modifications, or swing arm alterations may also be required. We recommend checking your bike specs to find the right sizes, or give us a call at (786) 242-5400 to review each detail and ensure the ordering process is handled correctly. Our fitment guide may also serve as a handy tool to ensure the correct wheel selection, the fitment guide can be found at the bottom of this blog article, or at the bottom of the description of any of our wheels.

Once the wheel fitment and sizing is selected, then comes the fun part; selecting your wheel style. RC Components develops each of their wheel designs with unique styles developed with CAD design and CAM programming to create designs with several looks ranging from aggressive styles, classic styles, and unique, funky styles. The best way to find the right design is by browsing through each style to find which best meets your taste.

How They’re Made

The RC Components wheels begin with an idea and are conceived into reality through the team of RC Components on site engineers who use CAD design and CAM programming. After drafting a carefully thought out design, prototypes are generated through state of the art CNC machining to cut the wheel to the exact design standard. The wheel is then put through rigorous testing procedures to ensure the wheel passes the designated safety requirements. Once determined safe, the new wheel is put into the fitment phase in which the wheel is installed onto a motorcycle for road testing. Once the wheel passes proper fitment and ride quality testing, the last task is to complete the wheel finish.

With the design and construction of the wheel being complete, the wheel is then hand-polished down to a mirror-like finish to ensure a brilliant finish to add to the staggering appeal. Once polished, the wheel can either be finished in a chrome, gloss black, matte black, or a contrast cut eclipse finish.

Wheel Finishes: Polished Aluminum

All RC Components wheels include a polished aluminum finish which features a hand-polished finish process which creates a clean, bright, shiny surface finish. The hand polishing process uses abrasives to remove imperfections within the surface metal such as nicks, lines, and scratches. As finer abrasives are used, the imperfections eventually become invisible to the naked eye. The polished aluminum will appear nearly identical to the chrome finish when received, however, exposure to the elements will cause the polished aluminum to lose its shine over time due to tarnishing. In order to keep the polished aluminum with a consistently high shine, a bi-weekly home polishing is recommended.

Chrome

The RC Components chroming process begins by hand-polishing the wheel down to a mirror like finish. The wheel is then put through the in-house chroming operation with a multi-step nickel chroming process to provide the highest protection against corrosion possible. To finish it off, a hexavalent chrome is used to get the most brilliant finish possible without any tints of yellow. The chrome plating (scientifically known as chromium plating), is electroplated onto the aluminum wheel creating both a decorative and protective layer which provides corrosion resistance, eases cleaning procedures, and increases surface toughness. Chrome wheels maintain a high shine throughout their entire life span and only require occasional cleanings with soap and water.

Semi Gloss Black

The semi gloss black finish is achieved through an anodizing process. Anodizing consists of an electrochemical process in which a protective coating of aluminum oxide is formed on the surface of the aluminum wheel. The aluminum oxide surface is a hard, durable, weather resistant surface which gives the aluminum wheel a deep, rich, metallic black appearance which cannot be peeled or flaked off from the wheel. Through the anodization process, the coating becomes part of the metal which makes for a tougher finish when compared to powder coating or chrome.

Matte Black

The matte black finish is achieved through a powder coating process. Powder coating consists of applying a dry color powder with an electrostatic charge to the metal wheel surface. This allows the color to attract to the metal surface. After the wheel has been coated, it’s baked at around 400 degrees Fahrenheit to finish the process. The powder coat finish can last around 15-20 years and is resistant to weather, corrosion, and chemicals, which makes powder coating a much more durable finish than traditional paint.

Contrast Cut Eclipse

The contrast cut finish is referred to as the “eclipse” finish. The eclipse finish offers a distinct contrast of black and raw aluminum to create a striking look which brings out the dark side of any motorcycle. The finish is achieved by starting with a black wheel blank in your choice of gloss black or matte black. The wheel design is then machined into the wheel to expose the raw aluminum. Once exposed, the raw metal edges give the wheel a unique finish unlike any other wheel finish on the market. Because of the unique and difficult process of achieving the finish, the eclipse finish is only offered for select wheel styles.

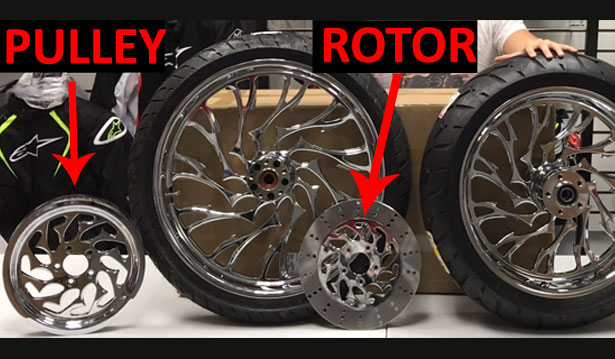

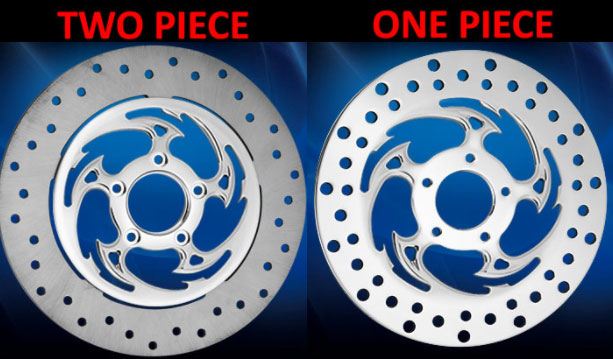

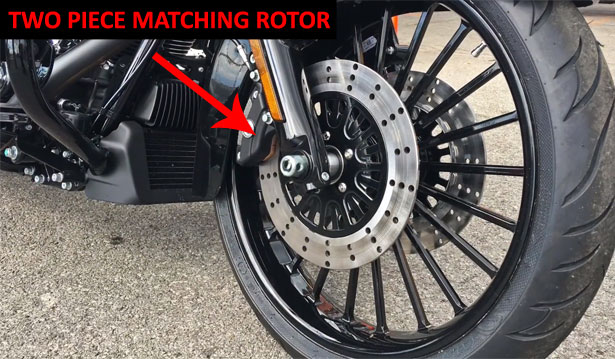

Matching Rotors, Pulley, and Air Cleaner

Each RC Components wheel style is offered with the option to add matching rotors, pulley, and air cleaner. Each rotor, pulley, and air cleaner is made alongside the wheel with state of the art CNC machining to cut to the exact design standard. RC rotors are designed in varying sizes ranging from 11.5”, 11.8” or 13” to match the application they’re made for. The rotors also offered in either a one piece, or two piece construction. The standard one piece construction is produced in one complete stainless steel piece and offers industry standard breaking performance. The two piece rotor is a more performance oriented rotor which is produced in two stainless steel pieces with the outer rotor ring being riveted to the central hub. This allows the two piece rotor to dissipate heat more effectively and reduces the possibility of warping. Because of the two separate pieces in this style rotor, the rotor is offered in a polished aluminum, chrome, or black finish, while the one piece rotor is only offered in a polished aluminum finish. While many motorcycle models offer the ability to reuse the stock rotors and pulley, a new rotor and pulley can enhance your ride's performance, and will give a more custom look to match the style of your new wheel. The matching pulley is also offered in the polished aluminum, chrome, and black finishes.

The RC Components air cleaners are not only designed to add more of a custom look on your bike, but the air cleaner also provides a high flow air filter which results in a superior combustion process. This results in increased maximum power as well as peak torque. The improved combustion process will also improve the fuel efficiency of your motorcycle and a better throttle response. A perfect addition for aesthetic reasons, and performance reasons.

Tire Options

After your wheel is produced, the tire of your choice can be mounted and balanced in house. This decreases the risk of scuffing or damaging the new wheel by allowing riders to make the decision to have the tire installed onto the new wheel directly in house, eliminating the need to use a separate shop to have the tire installed.

Warranty

We are confident in our RC Component products, and to back that up, a two year warranty is included with the purchase of any of our RC products. This includes warranty on the wheel structure, and the finish as well. The quality of our product cannot be observed without owning and using the product for a sufficient period of time, this is why we have decided to stand by our RC products with our warranty, just to ensure riders of the level of craftsmanship put into the wheel which they are purchasing.

At Accessories International (MotorcycleTire.com), we are proud to offer our riders support in finding the correct wheel to fit their bike and lifetime support on any orders placed, the way it should be. For any technical questions, recommendations, or general assistance give our team a call at (786) 242-5400.

overall rating: my rating: log in to rate

.png)